Assignments No –

I

Topic-Basic

Machine Design, Design of Shaft, Keys & Coupling

Date of Issue: 8th August,

2013 Date of

Submission: 14th August, 2013

1.

Explain the different stages in the design of machine elements.

2.

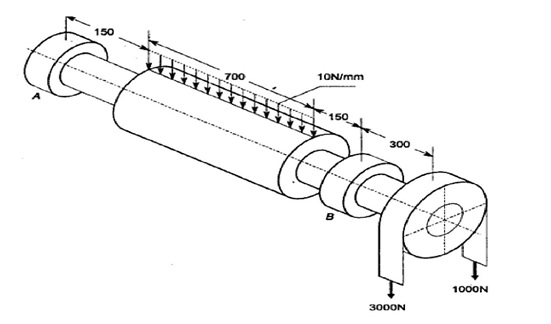

A armature shaft of a 40 kW, 720

rpm electric motor, mounted on two bearings A and B as shown in figure. Total

magnetic pull on the armature is 7 kN and it can be assumed to be uniformly

distributed over a length of 700 mm midway between the bearings. The shaft is

made of steel with a ultimate tensile strength of 770 N/mm2 and yield

strength of 580 N/mm2. Determine

the diameter of shaft if Km =1.5 and Kt=1.0, assume that

the pulley is keyed to the shaft.

3.

The problem is shown in the given

figure. A pulley drive is transmitting power to a pinion, which in turn is transmitting

power to some other machine element. Pulley and pinion diameters are 400mm and

200mm respectively. Shaft has to be designed for minor to heavy shock

ASME code for shaft design is suitable in this case

as no other specifications are provided.

In absence of any data for material

property, the allowable

shear for commercial

steel shaft may be

taken as 40 MPa, where keyway is

present in the shaft. For the given

condition of shock, let us consider Km = 2.0 and Kt =

1.5.

4.

What is key? How are the keys

classified? Draw neat sketches of different types of keys and state their applications.

5.

Discuss the function of couplings

and effect of key way cut into shaft. Explain the difference between rigid and flexible coupling.

6.

Design a cast iron protective

flange coupling to connect two shafts in order to transmit 7.5 kW at 720 rpm.

The following permissible stresses may be used:

Permissible shear stress for shaft, bolt

and key material = 33 MPa

Permissible crushing stress for bolt and

key material = 60MPa

Permissible shear stress for the cat

iron = 15 MPa

7.

Design a

bushed pin type

flexible coupling for

connecting a motor

shaft to a

pump shaft for

the following service conditions:

Power to be transmitted = 40 kW; speed of the motor

shaft = 1000 r.p.m.; diameter of the motor shaft = 50 mm; diameter of the pump

shaft = 45 mm. The bearing pressure in the rubber bush and allowable stress in

the pins are to be limited to 0.45 N/mm2 and 25 MPa respectively.

Note: On the last date of submission of your assignment, a

minor test of 20 marks will be conducted

Great post. These are the different stages in machine element,These plates are manufactured by the vendors using superior grade mild steel so as to ensure their longer service life and high tensile strength. ms plate price in Chennai will offer you an affordable price.

ReplyDelete