Saturday, August 17, 2013

Mechanical engg

WOODRUF KEYS are semicircular shaped, such

that, when installed, leave a protruding tab. The keyway in the shaft is

a semi-circular pocket, the mating part, a longitudinal slot. They are

used to improve the concentricity of the shaft and the

mating part, which is critical for high speed operation. The main

advantage of the Woodruff key is that it eliminates milling a keyway

near shaft shoulders, which already have stress concentrations.

High-Efficiency Belt Drives

Belt drives are frequently used in motor systems and offer advantages such as providing flexibility with positioning of the motor, allowing speed adjustments with the use of pulleys with differing diamaters, low maintenance requirements, decreased noise levels, and high efficiency. However, the efficiency of belt drives differ based on their type and condition.

V-type belts are most commonly used and offer efficiencies between 93 to 98%. However, their efficiency drops by about 4% by age and by an additional 5–10% with poor maintenance.

Wedge or cogged belts can maintain efficiencies that are around 2% higher than ordinary V-belts

Synchronous/flat/ribbed belts offer efficiencies between 96 to 99%, and require less maintenance. Advancements with these kinds of belts have widened their application possibilities, and it is worth exploring the potential to switch over to these.

Belt drives are frequently used in motor systems and offer advantages such as providing flexibility with positioning of the motor, allowing speed adjustments with the use of pulleys with differing diamaters, low maintenance requirements, decreased noise levels, and high efficiency. However, the efficiency of belt drives differ based on their type and condition.

V-type belts are most commonly used and offer efficiencies between 93 to 98%. However, their efficiency drops by about 4% by age and by an additional 5–10% with poor maintenance.

Wedge or cogged belts can maintain efficiencies that are around 2% higher than ordinary V-belts

Synchronous/flat/ribbed belts offer efficiencies between 96 to 99%, and require less maintenance. Advancements with these kinds of belts have widened their application possibilities, and it is worth exploring the potential to switch over to these.

The articulate or jointed arm robot (or

sometime called Anthropomorphic arms) closely resembles the human arm.

The mechanical structure has at least three rotary joints which forms a

polar coordinate system. The Figure shown an articulate robot

with 6 degree of freedom. The basic three rotary joints able Arm swap,

shoulder swivel and elbow rotations. Additional 3 revolute joints (Roll,

Yaw, Pitch) and one prismatic joint allow the robot to point in many

directions, and then reach out some radial distance.

Application area:

Arc welding

Spot welding

Assembly

cleaning/spraying

Cutting

Deburring

Die casting

Gluing/sealing

Grinding/polishing

Injection moulding

Machine tending

Material handling

Packing

Palletizing

Picking

Pre-machining

Press brake tending

Application area:

Arc welding

Spot welding

Assembly

cleaning/spraying

Cutting

Deburring

Die casting

Gluing/sealing

Grinding/polishing

Injection moulding

Machine tending

Material handling

Packing

Palletizing

Picking

Pre-machining

Press brake tending

Wednesday, August 7, 2013

Mechanical Vibration Assignmnet No 1

Assignments No –

I

Date of Issue: 8th August,

2013 Date of Submission: 14th August,

2013

1.

Represent

the periodic motion given in figure 1 by harmonic motion

Figure 1

2.

Find the

sum of harmonic motion of equal amplitude but of slightly different

frequencies. Discuss the beat phenomenon that results from this sum.

3.

Split up

the harmonic motion 8 sin (ωt + π/4) into two harmonic motions one of which has

amplitude of 10 and phase difference zero.

4.

A steel

shaft 6 cm diameter and 50 cm long fixed at one end carries a flywheel of

weight of 1000 kgf and radius of gyration 30cm at its free end. Find the frequency

of free longitudinal transverse and torsional vibration E= 2 x 106

kgf/ cm2, C = 3.8 x 106 kgf/ cm2.

5.

A shock

absorber is to be designed so that its overshoot is 10% of the initial

displacement when released. Determine the damping factor. If the damping factor

is reduced to one half this values, what will be the overshoot?

6.

A simple

U tube manometer filled with liquid is ahown in figure 2. Calculate the

frequency of resulting motion if the minimum length of a manometer tube is

0.15m.

Figure2

7.

A gun

barrel having mass 560kg is designed with the following data: Initial recoil

velocity 36 m/sec, recoil distance on firing 1.5 m

Calculate:

(a)

Spring

constant

(b)

Damping

coefficient

(c)

Time

required for the barrel to return to a position 0.12 m from its initial

position

8.

A

vibratory system is defined by the following parameters:

m

= 3kg, k = 100 N/m, C = 3 N- sec/m. Determine

a. The

damping factor

b. The

natural frequency of the damped vibration

c. The

logarithmic decrement

d. The

ratio of two consecutive amplitudes

The number of cycles after which the original

amplitude is reduced to 20 percent.

Note: On the last date of submission of your assignment, a

minor test of 20 marks will be conducted

Design of Machine Elements - I Assignmnet No I

Assignments No –

I

Topic-Basic

Machine Design, Design of Shaft, Keys & Coupling

Date of Issue: 8th August,

2013 Date of

Submission: 14th August, 2013

1.

Explain the different stages in the design of machine elements.

2.

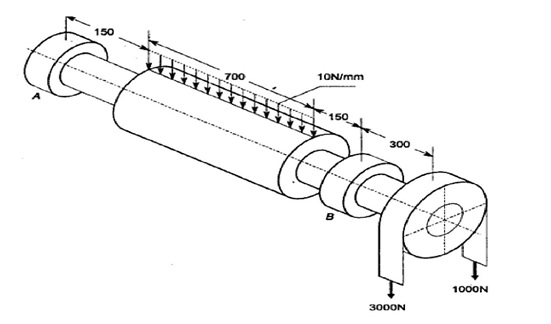

A armature shaft of a 40 kW, 720

rpm electric motor, mounted on two bearings A and B as shown in figure. Total

magnetic pull on the armature is 7 kN and it can be assumed to be uniformly

distributed over a length of 700 mm midway between the bearings. The shaft is

made of steel with a ultimate tensile strength of 770 N/mm2 and yield

strength of 580 N/mm2. Determine

the diameter of shaft if Km =1.5 and Kt=1.0, assume that

the pulley is keyed to the shaft.

3.

The problem is shown in the given

figure. A pulley drive is transmitting power to a pinion, which in turn is transmitting

power to some other machine element. Pulley and pinion diameters are 400mm and

200mm respectively. Shaft has to be designed for minor to heavy shock

ASME code for shaft design is suitable in this case

as no other specifications are provided.

In absence of any data for material

property, the allowable

shear for commercial

steel shaft may be

taken as 40 MPa, where keyway is

present in the shaft. For the given

condition of shock, let us consider Km = 2.0 and Kt =

1.5.

4.

What is key? How are the keys

classified? Draw neat sketches of different types of keys and state their applications.

5.

Discuss the function of couplings

and effect of key way cut into shaft. Explain the difference between rigid and flexible coupling.

6.

Design a cast iron protective

flange coupling to connect two shafts in order to transmit 7.5 kW at 720 rpm.

The following permissible stresses may be used:

Permissible shear stress for shaft, bolt

and key material = 33 MPa

Permissible crushing stress for bolt and

key material = 60MPa

Permissible shear stress for the cat

iron = 15 MPa

7.

Design a

bushed pin type

flexible coupling for

connecting a motor

shaft to a

pump shaft for

the following service conditions:

Power to be transmitted = 40 kW; speed of the motor

shaft = 1000 r.p.m.; diameter of the motor shaft = 50 mm; diameter of the pump

shaft = 45 mm. The bearing pressure in the rubber bush and allowable stress in

the pins are to be limited to 0.45 N/mm2 and 25 MPa respectively.

Note: On the last date of submission of your assignment, a

minor test of 20 marks will be conducted

Subscribe to:

Comments (Atom)